Website design, development and copywriting can be done faster, more accurately and creatively with the help of Lean manufacturing techniques, which help companies around the globe accomplish industry-leading results. Lean is a production practice that helps identify resource use that’s not directly tied to creating value for customers, so it can be eliminated. In essence, Lean preserves value with less work. Some common objectives Lean aims to achieve:

- 1/2 the hours of human effort

- 1/2 the defects

- 1/3 the hours of engineering effort

- 1/2 the factory space for the same output

- 1/10th or less of in-process inventories

Forms of Lean have been utilized by companies like Toyota since the 1960s, achieving individual productivity rates in excess of 35%, versus American and Canadian companies, which attain productivity rates of 5.2% and 3.9%, respectively. In fact, this process improvement system has been credited with helping Toyota achieve steady growth for decades, from a small company to the world’s largest automaker.

Canada-based Value FLOW Systems (VFS), which studies and implements Lean throughout Canada, the US and Europe, recently conducted a workshop at Wardell Business Advisory in Vancouver, BC, to demonstrate the power of the Lean process.

Lean Workshop: The Fictitious Boat Factory

Participants joined a production line and were called on to make as many cardboard sailboats as possible in 30 minutes. With the ‘workers’ manning each of the work stations, and everyone going full out, the group was hard pressed to build 20 boats, while pumping 30 defective hulls into the process.

For a second round, the VFS team made a couple of minor layout changes to the production line, including re-organizing the bottleneck area. During the next 30-minute period, the team managed to build 36 boats with only one defective hull, which was detected and repaired immediately. This translated to an 80% output improvement, a 70% reduction in lead time, and a 97% reduction in defects. The amazing thing was that nobody worked any harder; in fact, the participants were unanimous in stating that the work pace was very relaxed.

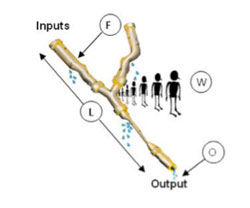

A FLOW model compares the process to a pipe, said VFS President Ken Yates, pointing out that there are four relevant features that need to be addressed. Since no process is perfect, he explained, there will always be faults (F) in the pipe (or process). The time it takes to produce a product is represented by the length (L) of the pipe and the capacity by its opening (O). Finally, the process is operated by the workforce (W).

“By studying each of these aspects, F–L–O-W, the group learns how to modify the way that the participants perform their tasks,” explained Yates, “The team then gets back to work and without hurrying, builds twice as many boats in the same time period, with an astounding reduction in defects and every boat being produced in less than half the time.”

While Lean was effective with cardboard sailboats, it proves to work just as well in the real world, in essentially any industry. It consistently helps companies increase output while reducing costs, waste, inventory levels and delivery times. This ultimately results in increased product quality, productivity and competitiveness.

Yates indicated typical outcomes after 15- to 20-day improvement programs include:

- 25%-90% productivity improvements

- 30%-80% inventory and stock reductions

- 30%-80% response time reductions

- 20%-30% reduction in square footage required

- 30%-80% lot size reduction

Applying Lean to Website Production

So how does all this apply to website production? Well, suggested Yates, it’s best to start with client requirements. “The client likely wants a first-class website, including every conceivable advantage, as soon as possible at a competitive price,” he said.

To achieve this, Lean puts the following elements under the microscope:

F (Faults) – Reduce Waste and Defects

No client is willing to tolerate errors in a website. Lean moves designers, developers and copywriters toward an ‘error-proof’ process, where it becomes difficult to do something incorrectly, and all input is focused on ever-improving quality — from the point of view of the client.

Avoid Overproduction and Excess Inventory

Don’t produce more than is needed, or before it’s needed. While this generally applies to manufacturing, it can be applied to website production. For instance, calling for 30 pages of web copy when only 20 are required, or engaging a costly content management system when a simple blogging solution like WordPress would be sufficient. To avoid waste, designers, developers and copywriters should discuss and outline needs, concerns and opportunities within their respective areas of specialization.

Transportation

Despite the advent of the Internet, this rule still applies. Even small web development agencies are guilty of unneeded movement of materials, including what might be considered trivial items, such as reference material, CDs, or even pens. Measurable efficiencies can be gained by having the right equipment at each workstation. Some companies literally outline the equipment in each area, so you know at a glance if anything is missing.

Inappropriate Procedures

This is a killer in the website production world. Developing a wireframe before the website’s objectives and call to action if firmed up. Developing apps before an audience’s desires or needs are fully explored. Copywriting before the information architecture and link structure is established. All stakeholders need to be on the same page and work as a cohesive unit.

Waiting and Delays

Unfortunately, the waiting game is quite common with web designers, developers and copywriters. In fact, Webcopyplus has been called into projects where designers have been waiting for clients to provide web copy for more than a year. Or developers don’t receive designs on time, which forces overlap onto other projects, causing additional stress and conflict. All players must respect their commitments and their colleagues’ needs, and deliver quality goods on time. Clients, too, need to understand their timelines, and commit to meeting them.

Rejects and Rework

Defects equal pure waste. Every item, including design, programming and copywriting, must be made to customer specifications.

Poka Yoke

Apply Poka Yoke, a Japanese term that means "fail-safing" or "mistake-proofing." Design templates, tools and software so they can only be used the correct way. Consider electrical plugs with the different prongs.

L (Length) – Reduce Global Lead Time

Meeting delivery dates is one of the weakest service components delivered by Canadian and US companies, something the website production industry is guilty of too. Lean uses long-established concepts to ensure rapid response time and reliable forecasts of finishing times.

Process Mapping

Systematically question each activity in the current value stream, and develop the right process. When to and how to decide on the software platform, SEO tactics, and so on. It helps create a ‘pure pull’ environment, where you keep the order moving, versus a ‘pure push’ environment, where you just keep working for the sake of working, and spin your tires.

O (Opening) – Increase Capacity

Every process has a bottleneck, a constraint that restricts output. Becoming Lean means being able to identify the constraint, and focus effort where it counts most. This could entail people skills, resources, parts, hardware limitations, software accessibility, and so on.

Dealing with Bottlenecks

Some standard ways to open up bottlenecks and improve flow include:

1. Cross lunch hours and breaks

2. Extend working hours

3. Control quality before bottlenecks

4. Apply DOCTOR / NURSE principle to bottleneck

5. Reducing setup time at bottleneck is the priority

W (Workforce) – Involve the Workers in Continuous Improvement

According to Yates, this is possibly the greatest overlooked resource in Canadian and US industries. “In a Lean organization,” he said, “Every employee is involved in creating improvement on a daily basis.” This can be achieved by applying Lean tools, including 5S.

5S

- Sort – Separate and remove clutter and unneeded items

- Set in Order – Organize what’s left

- Shine/Scrub – Clean area, storage, equipment, etc. and inspect for warning signs of breakdowns

- Schedule/Standardize – Set up 5S supply area (with resource material, labels, coloured tape, etc. ) and schedule time and responsibility for restoring work area to its proper condition regularly

- Score/Sustain – Audit area on a regular basis, and expand 5S to other areas

“By introducing these types of Lean tactics to a web development team or agency, website projects can be completed more rapidly, precisely and resourcefully,” said Yates. “Because Lean is largely a ‘team’ thing, it tends to get groups involved in the highly imaginative process of on-going brainstorming. People have fun when they are creative, and teams have more fun than individuals.”

If stimulating a team with Lean tools increases everyone’s enjoyment, the web professionals win, and so do their clients.

About Rick Sloboda (the author of this post)

Rick Sloboda is a Senior Web Copywriter at Webcopyplus Professional Web Writing Services, which helps businesses boost online traffic and sales with optimized web copy. He speaks frequently at Web-related forums and seminars, and conducts web content studies with organizations in Europe and the U.S., including Yale University.

Joey

Looks like a great post, i only read small portions yet, but will definitely read the whole thing.

Regards,

J H

Ward O.

The topic of lean thinking is a very interesting one. Applicable in all kinds of business throughout the world and also in web design and development. This post is OK, although the views presented here are not comprehensive.

For further study of this concept I would recommend reading this book:

“Lean Thinking: banish waste and create wealth in your corporation” by Womack & Jones (various editions, buy a recent one ;-) ).

It is a well-known, very practice-oriented book. It contains some great examples that illustrate each part of the lean thinking concept. Some of these examples might serve as great inspiration for your own business.

Good article anyway…

Ronaldo

great article!

I often find myself trying to optimize “web production”.

Since I have no background on management, I’ve been reading several articles on project management, agile methods and such so I can improve all the stages of website production. This article have some nice ideas for work optimization. I don’t advocate any particular methodology but learning from several of them.

DesignerWall

Awesome Article. As always :)

Andy Birchwood

I’m not totally convinced by this idea. If I were producing the same website time after time, I would be able to apply the principles. But it’s the resource of the client that dictates the “production line” – and you have to make sure your process is flexible enough to accomodate them, or you’ll be turning away perfectly good contracts.

Web Developers

Bookmarked the post, definitely needs a further reading.

nazpro

intersting topic..i like it>>

and the Poka Yoke…..it’s new

thanx

wes

Interesting application of lean. I went through training at a warehouse, corporate setting, but I’ve never directly applied it to my web work. Once people were on board, and this was the hard part, it produced some good results.

Jordan Walker

Interesting outlook for web development and programming methodologies.

Robert Lindstedt

Interesting to see that regular BPM / Lean is going to transform over in to web design, I would like to see the first “real” mapping of this to a real case with the benefits achieved in a creative web project.

Lourens

Thank you for this article, very interesting and very new for me :)

Altax

That was a great information. Thanks for the post.

Dimi

Great topic indeed, took some valuable notes from this, thanks!

Brazil Business and Investments

Great article, as always. I`ll try to execute this in my company. Tks!

Lena Tailor

What an excellent list of resources to go through. Thanks and Bookmarked.

designfollow

thank you very much for the great information.

Andrew

Great information here. Definitely worth a second read.

Thor Brink

Really enjoyed the post.

Would be cool to see a second part where Lean has been applied in the webdesign business, maybe amongst the followers of the blog. Just a thought.

Jon

Really interesting! Would love to learn more about LEAN

kgordon

Lean manufacturing techniques are a genius idea to cut production time in half. By putting half the hours, a third of the hours of engineering effort, half the factory space, resulting in half of the defects and a tenth or less of in process inventories, it will benefit the web design industry by allowing the client t get “a first class website as soon as possible at a competitive price.” While I think this post is good topic and a productive outlook, I feel like the views are not presented thoroughly to the readers.

Celeste Combs

I’m a information architect and wireframe guru and I can say we have produced websites very quickly by using IA and wireframes and including development on each review. Once we have firmed up aspects of a website, we release that to dev, then we also use the wireframe specs to QA. Awesome article!

Sammie Barlip

Hey there! I’m at work browsing your blog from my new iphone 4! Just wanted to say I love reading your blog and look forward to all your posts! Keep up the outstanding work!

Robert T.

After having a website created, it’s important to do the proper steps for search engine optimization. Without doing marketing for a website, it would be pretty much useless unless you have some form of marketing to drive the traffic there.

We do Direct Marketing, which is a direct unique visitor that would be searching for your specific product or service. These type of leads are much more beneficial than indirect flyers or emailing.

Cook

good article….loved it

warehouse management system

Reducing work time for website designers is really helpful. Now they won’t get caught up with so many hours on a chair in front of their PC. With fast turnover of their work I believe they can also have brighter opportunity to earn more. Is there also a way for you to make a tutorial for easy website making? Hope you can have it on your next blog post.

WMS

staypuftman

This is a bit ridiculous, considering the client is so crucial to the equation in design. When you are building a boat, a retailer handles ‘clients’ – they are called customers. In design, the client is usually in your face, all of the time.

Imagine having a boat customer needing to approve each decision the boat builders are making. You could never achieve those levels of efficiency. That is the world of web design more often than not.

Rich

I believe Lean as discussed in this article has merit in the design arena. For instance, having well-planned, efficient processes in how you educate clients, extract info from them, and how you bring about, implement and manage steps in design and collaboration, can all help save time and money, and get the clients the ultimate results.

sbobet

All a beautiful view. But I like the design of Legwork studio.

gclub

Techniques offer better not see too cluttered.

Clea Walford

Thanks a lot for the great article

sheridap

Good article, however, process improvement in the manufacturing sense doesn’t apply to the creative process of innovating on NEW work.

Boat manufacturing can be improved so long as the boat design never varies. What if the boat design had to change with each unit produced?

imho, designers are better served to develop agile/iterative design habits and learn to structure facilitated client meetings.

Web Design

Love it thank yoU

Andy Griffiths

Pretty deep that actually. Lots of info here, will have to try and divulge it properly when get an hour or so to read through in more detail. Thanks

crash

3M is famous for having toyed with this idea and found it removed all of the creativity from their scientific teams who were used to dabbling with products in order to make them better. One of these ideas was the creation of their sticky-notes.

The most famous version of this lean philosophy is Lean Six Sigma which also has some heavyweight criticism:”A Fortune article stated that “of 58 large companies that have announced Six Sigma programs, 91 percent have trailed the S&P 500 since”

It’s an interesting article, but I don’t think taking all of the creativity out of web design and development is the way to a better product. I believe that web design and development needs to have some chaos and inefficiencies to create an original product.

K

Website Design

To me your example of ‘lean’ just means normal project management. Research and plan out the project in true and tried phases.

Avangelist

I have been looking at a lot of management techniques for processes. So far the most successful one I have applied was the KJ method for solving problems.

We used this to asses the requirements of a web project. The biggest part of it was giving everyone the opportunity to voice the opinion in a concise manner and then to manage the priorities of it.

The Lean concept doesn’t, to me, seem like anything at all, other than common sense. Using the example in the case study, I don’t know what the reason behind the fault that caused the damaged hulls, and what problem solving skills were employed to resolve it and generate such a massive improvement in performance of the chain.

I think perhaps with a fully fleshed out example it would be easier to see how these manufacturing processes can be applied to web design.

hostrightnow

Nice information is there.Techniques offer better thanks for making a useful post

yohan

thanks for the info :)

arieff

Techniques offer better not see too cluttered.

nice post..

Tristan

Interesting article but I’m not sure the connection with website development is all that clear. Organsing workstations so rigidly for example doesn’t really seem like such a brilliant idea. Perhaps this is more suited to production line type websites that are heavily templated.

ardhan

very nice information :D

utari

nice information, thanks

code pixelz media

very good. I like the way you present your content.

eric

thanks for share…

nice post :)

kai

thanks for information… that’s great article

redsun

Great article

ospop shoes shop

Bookmarked the post, definitely needs a further reading.

Tom

There are some useful points in here, but 95% of it is corporate enrichment nonsense. For example, ‘Apply DOCTOR/NURSE principle to bottlenecks’ – no doubt if I Google this unexplained powerphrase I will just drill down to the next semantic level of useless jargon.

I’m not a person averse to new ways of working, but I don’t believe that being able to construct fancy phrases and concepts can lead to 80% efficiency improvements; and are you seriously telling me that by ‘widening our pipe’ and putting bits of coloured tape on our tools we can sell off a quarter of our office space? It’s just another sector for management coaches to poke their nose into and justify their existence.

Melvins

You have shared very helpful and Insightful article. Thanks for sharing.

Los Angeles Web Design

Ken Yates

Re Comment #47: Tom, Thanks for the opportunity to expand on the doctor/nurse principle. It deserves fuller explanation because it can be a critical element to expanding process productivity. Let’s start by looking at a process as a ‘pipe’ with a variable diameter, the diameter at any one point along the pipe representing the capacity to add value at that point. The area with the smallest diameter will act as a bottleneck for the entire pipe. That is, no matter how much (material, information, etc.) goes into the process pipe, what comes out the other end (downstream / client deliverable) will be restricted to how much can get through the smallest diameter within the pipe. This is the bottleneck. Here’s why it is of critical importance. Let’s say you run a highly successful business with sales of $12,000,000 per year, assuming for the sake of demonstration that all of your ‘product’ is processed through the same steps. If your company operates one shift, it will be in operation about 2000 hours per year. Your billing capacity therefore will be $12,000,000 divided by 2000 hours, or $6,000 per hour ($100 per minute). No matter how hard or how efficiently work is done anywhere else in the process, you can’t get any more through than what the bottleneck can handle.

From a Lean point of view, the worker (or machine) at the bottleneck is like the heart surgeon in your company. Everything depends on what he/she/it can produce. In an operating room when a heart surgeon operates on a patient, he cuts through the epidermal layers, opens the rib cage and is ready to cut into the heart. At this point he doesn’t go back to his locker to get a scalpel; he calls for it and a nurse places it in his hand.

A similar thing can happen at your bottleneck. When the worker there (your company’s heart surgeon) needs something (a tool, jig, die, pattern, etc.) if he stops what he’s doing to get what he needs, you lose $100 a minute. However, if some other worker is available to hand him what he needs when he needs it, the bottleneck opening is maximized. This is the doctor/nurse principle.

How does it work in reality? One of my clients, a wooden truss maker, had a bottleneck at the assembly table. When you assemble a truss, you place a number of carefully cut pieces of lumber in a pattern and join them with metal plates. Time was constantly being lost by the truss assemblers (doctors) fetching the appropriate plates. With the use of one non-bottleneck worker (nurse) to hand the correct plates to the assemblers as needed, total productivity was increased by 27%.

How does this work in website production? First, you need to know where the major process constraint (bottleneck) is. Next, you need to differentiate between value added (VA) and non-value added contribution at the bottleneck and what work absolutely must be done by the ‘surgeon’ and what can be done by a ‘nurse’ in order to allow the surgeon to spend a greater proportion of his time creating value. The results can be remarkable, and when bottleneck techniques are combined with other Lean tools, an 80% efficiency improvement is not out of sight.

Now, as for office space, it is my experience, based on my personal observation over the past 14 years, that the vast majority of North American companies occupy too much space, leading directly to wasted movement, transportation, work in process and process time. I’m not saying that workers should be crammed into little cubicles; rather the space requirement should be assessed in terms of human efficiency and comfort. When you do this, in combination with the application of Lean thinking tools such as the Pareto principle (80-20 rule) and layout design, the worker is more comfortable and more productive. When you apply this kind of thinking to the bottleneck, the sky’s the limit.

get paid to upload

Have you ever regarded as including much more videos to your blog posts to maintain the readers additional entertained? I necessarily mean I just learn by way of the total article of yours and it was very very good but considering that I am additional of a visual learner,I discovered that to be additional useful. Just my my strategy, Good luck

Juno Mindoes

Recently i am looking fot the white iphone 4 conversion kit. If you have any recommendation, plz tell me. I will be very grateful!

altın çilek

very good. I like the way you present your content.

hcg damla

Bookmarked the post, definitely needs a further reading.

dexx

Associate researchers. Dr. Shah, people with ADHD “different thinking” they know better than laboratory measurements, but this situation in real life it could do with this work a success and said they did not know çevirmediklerini turn.

orhanbt

This is verry good

طراحی سایت

yeah, i agree, its really perfect, good luck

web design / طراحی سایت

its really perfect, good luck

j_hatfield

Good ideas, I also found this link which also helps me with my production at work:

http://www.back40design.com/news/m.blog/22/5-tips-for-a-better-workflow

Web Design Melbourne

Good information and idea!

Lovro

Excellent article, i’ll try to put this in action! :)

Matt Wright

As a former Six Sigma Black Belt and now the owner of a web design company I can tell you all the above information is true. It’s actually made me think more about using my Six Sigma (lean) skills for our own process. Something I should have thought about before. Thanks for the article.

DymoLabels

hi sir

i really like your collection

thanks for sharing this great tips

thanks